Tesla Gigafactory 1: Revolutionary Powerhouse Supercharged

Contents

- 1 Overview of the Gigafactory’s location in Nevada

- 2 Key features and capabilities of the Tesla Gigafactory 1

- 3 The impact of the Gigafactory on Nevada’s economy

- 4 Environmental sustainability efforts at the Gigafactory

- 5 Challenges faced during the construction and operation of the Gigafactory

- 6 Future plans for expansion and additional Gigafactories

- 7 Collaborations and partnerships with other companies in the battery industry

- 8 Conclusion: Tesla Gigafactory 1’s role in the future of clean energy and transportation

- 9 Author

In the ever-evolving world of clean energy, the importance of battery production cannot be overstated. As the demand for electric vehicles (EVs) continues to soar, the need for high-performance, cost-effective batteries has become paramount. Batteries are the heart and soul of electric vehicles, powering their motors and enabling the zero-emission transportation that is crucial for a sustainable future.

The global shift towards electrification has put immense pressure on battery manufacturers to keep up with the growing demand. Conventional battery production methods have struggled to meet the sheer scale required to support the rapid expansion of the EV market. This is where Tesla, the pioneering electric vehicle company, has stepped in with its revolutionary Gigafactory 1 in Nevada.

By establishing a massive, vertically integrated battery production facility, Tesla is not only addressing the supply chain challenges but also driving down the costs of battery packs. This, in turn, is making electric vehicles more accessible to the masses, accelerating the transition towards a sustainable transportation ecosystem. The Gigafactory 1 is a testament to Tesla’s relentless pursuit of innovation and its commitment to transforming the way the world views and utilizes energy.

Overview of the Gigafactory’s location in Nevada

Hidden deep within the parched desert of Nevada, the Gigafactory 1 is a monolithic example of Tesla’s aspirations and goals [to continue to expand in solar through manufacturing]. Strategically situated just outside Reno, the Gigafactory boasts a cavernous 3.3 million square feet of space in size and is one of the largest buildings by footprint in existence on our planet today.

Nevada was not an accidental location choice for this revolutionary facility. The state’s business-friendly policies, its extensive renewable energy resources and the desirable proximity to nearby Tesla vehicle manufacturing operations in California were ideal. With Nevada’s historic backing of environmentally friendly energy and other attempts to promote sustainability, doing something sweet in the Silver State was salted by incentives.

Gigafactory 1 is a massive facility and really, it needs to be. The facility takes up 100 football fields and will build batteries faster than any other gengtoto lithium-ion battery factory in the world once it’s fully operational. It would a which is glossy demonstration of ” bias Tesla’s alongside path to the overwhelming battery market change in our energy future.

Key features and capabilities of the Tesla Gigafactory 1

Gigafactory 1 indeed represents the epitome of innovation and efficiency for Tesla. The factory is actually conceived of as a self-contained, vertically integrated battery production center: every aspect of the manufacturing process has been designed from scratch to be optimized as much as possible in terms both cost and environmental sustainability.

Especially as it has to do with the renewable energy features of Gigafactory. All of this is being powered by an extensive bank of solar panels, which provide enough power to supply most visitors’ energy needs. This dedication to living off of renewable energy not only reflects the company’s values, but also ensures that batterires built at the Gigafactory will have an incredibly low carbon footprint.

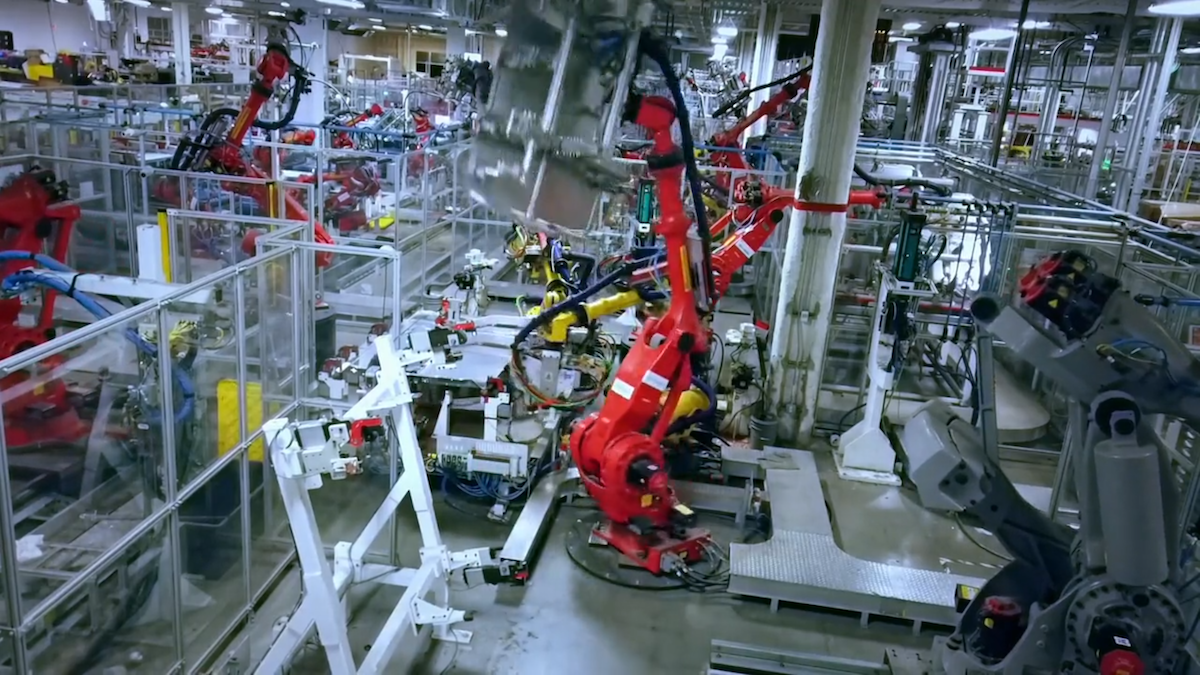

Lincoln, for one is driving that with innovative processes all in the solar-powered Gigafactory just outside Sparks. The facility even uses advanced automation and robotics to make cells, modules, and packs much faster than ever before. Greater automation ensures not just increased productivity, but also reduced personal error for consistent quality and dependability in the final products.

Furthermore, the vertical integration of Gigafactory provides unprecedented synergy and optimizes the raw material to battery value-chain. This allows Tesla to manufacture battery cells, modules and packs in one facility, giving it control over the entire process from start to finish—a big advantage that should help streamline production processes lowering costs while ensuring a reliable supply of high-quality batteries.

The impact of the Gigafactory on Nevada’s economy

Nevada: Tesla Gigafactory 1, Sparks In addition to the thousands of newly created jobs, a wide variety of companies that support manufacturing have moved into the region.

At the time of its announcement, Tesla said it would create some 6,500 jobs at the Gigafactory when fully operational. It was an infusion of skilled labor and high wages that started a chain reaction in the local economy, from housing demands to consumer goods—and every bit had it covered.

Just as important to Tesla, though perhaps less obvious in terms of job creation is the Gigafactory’s string effect— luring a spectrum of 19 other non-Tesla yet industry-specific suppliers either re-locating or expanding their current operations into Nevada. Many battery component suppliers, logistics providers and other supporting businesses are now operating in the state in order to support Gigafactory’s operations. This has in-turn created even more jobs, and further cemented Nevada as a hotbed for clean energy & high-tech manufacturing.

Job creation is not the only way that Gigafactory has an impact on local economies. The facility has helped produce major tax revenues for the state that are used to fund roads, schools and other vital public services. Nevada’s economic recovery has been accelerated by this influx of resources and the state now faces an unprecedented opportunity to become a national leader in America´s clean energy revolution.

Environmental sustainability efforts at the Gigafactory

The first Gigafactory from Tesla is designed to be able to expand and provide the electric vehicle maker with batteries at a cheaper rate, made possible through economies of scale that should lower costs by 30 percent. This design and these operations form a centre that minimizes the carbon footprint created by everything practical from current to future life on our planet.

One of the Gigafactory’s most impressive sustainability features is its reliance on renewable energy. As previously explained, a large part of the facility runs on solar panels that generate enough electricity to power most of what the Gigafactory needs. In addition to being consistent with Tesla’s broader objective of driving down the cost and environmental impact, this renewable energy commitment could reduce the production chain emissions by up to 69% compared with those produced using natural gas-powered utilities.

In addition to its solar power use, the Gigafactory also uses a number of other green practices in order offset their environmental impact. With advanced water recycling systems in place to dramatically reduce the building’s overall reliance on potable water, as well as robust waste management protocols ensuring the vast majority of all site and construction related waste is either recycled or repurposed;

Additionally, the Gigafactory was constructed with sustainability and energy efficiency in thoughts. The building has been designed for optimal heat regulation, so heating and cooling systems do not have to be used as frequently or are needed at all. Other energy-efficient features have been incorporated too, including LED lighting and sophisticated HVAC systems to reduce the facility’s environmental impact.

Challenges faced during the construction and operation of the Gigafactory

The development and operation of the Tesla Gigafactory 1 have not been without their fair share of challenges. Building a facility of such unprecedented scale and complexity has required overcoming a multitude of logistical, technical, and regulatory hurdles.

One of the primary challenges faced during the construction of the Gigafactory was the sheer scale of the project. Coordinating the simultaneous construction of multiple production lines, support facilities, and infrastructure systems required meticulous planning and execution. The Tesla team had to navigate a complex web of suppliers, contractors, and regulatory agencies to ensure that the project remained on schedule and within budget.

Another significant challenge was the need to develop and implement new manufacturing processes and technologies to achieve the Gigafactory’s ambitious production goals. Traditional battery production methods were simply not equipped to handle the massive scale and rapid pace required by the facility. Tesla had to invest heavily in research and development to create innovative solutions that could meet the Gigafactory’s unique demands.

Regulatory compliance has also been a persistent challenge for the Gigafactory. The facility’s operations involve the handling of hazardous materials, the management of waste, and the adherence to strict environmental regulations. Navigating this complex web of rules and regulations has required a dedicated team of experts and close collaboration with local and federal authorities.

Despite these challenges, the Tesla team has demonstrated an unwavering commitment to overcoming obstacles and delivering on the Gigafactory’s ambitious goals. The facility’s continued operation and expansion are a testament to the company’s resilience and its ability to innovate in the face of adversity.

Future plans for expansion and additional Gigafactories

As the Tesla Gigafactory 1 continues to revolutionize the battery industry, the company’s sights are set on even greater achievements. With the success of the Nevada facility, Tesla has unveiled plans for the construction of additional Gigafactories around the world, each one designed to further accelerate the transition to sustainable energy.

One of the key drivers behind Tesla’s expansion plans is the growing global demand for electric vehicles. As more and more consumers embrace the benefits of zero-emission transportation, the need for high-quality, cost-effective batteries has become increasingly urgent. By building a network of Gigafactories, Tesla aims to ensure a reliable and abundant supply of batteries to meet this burgeoning demand.

But the Gigafactory expansion is not just about increasing production capacity. Tesla is also focused on continually improving the efficiency and sustainability of its battery manufacturing processes. Future Gigafactories will incorporate the latest advancements in automation, energy efficiency, and renewable energy integration, further solidifying the company’s position as a leader in the clean energy revolution.

Moreover, Tesla’s Gigafactory vision extends beyond just battery production. The company is exploring ways to leverage the facilities’ capabilities to support other aspects of the sustainable energy ecosystem, such as grid-scale energy storage solutions and renewable energy generation. By diversifying the Gigafactories’ product offerings, Tesla aims to create a comprehensive, vertically integrated platform that can power the transition to a more sustainable future.

Collaborations and partnerships with other companies in the battery industry

As the Tesla Gigafactory 1 continues to push the boundaries of battery production, the company has recognized the importance of collaboration and partnerships within the industry. Recognizing that no single entity can single-handedly transform the global energy landscape, Tesla has actively sought out opportunities to work with other leading players in the battery and clean energy sectors.

One of the most prominent examples of such collaborations is Tesla’s partnership with Panasonic. The two companies have worked closely together to develop and refine the battery cell production processes at the Gigafactory 1. Panasonic’s expertise in battery technology, combined with Tesla’s innovative approach to manufacturing, has resulted in significant advancements in cell efficiency, cost, and performance.

Beyond its partnership with Panasonic, Tesla has also forged alliances with a range of other companies, including battery raw material suppliers, recycling specialists, and energy storage solution providers. These collaborations have not only strengthened the Gigafactory’s supply chain but have also enabled the development of more comprehensive, sustainable energy solutions that can be deployed across a variety of applications.

Moreover, Tesla has actively engaged with academic institutions and research organizations to stay at the forefront of battery technology innovation. By fostering these partnerships, the company is able to tap into the latest scientific breakthroughs and incorporate them into the Gigafactory’s manufacturing processes, ensuring that its products remain cutting-edge and highly competitive.

Conclusion: Tesla Gigafactory 1’s role in the future of clean energy and transportation

The Tesla Gigafactory 1 in Nevada stands as a testament to the power of innovation, determination, and a relentless pursuit of a sustainable future. This colossal facility has not only revolutionized the battery production industry but has also paved the way for a more electrified and environmentally conscious world.

Through its commitment to renewable energy, advanced manufacturing processes, and a vertically integrated approach, the Gigafactory 1 has demonstrated that large-scale, cost-effective battery production is not only possible but essential for the widespread adoption of electric vehicles. By driving down the costs of batteries and ensuring a reliable supply, Tesla is making electric mobility accessible to the masses, accelerating the transition away from fossil fuel-powered transportation. If you like reading this article then please consider reading our article about Australia.